Used CNC Welders: Need to Lower and fabricate with welds? Used CNC welders are offered For each and every form of welding and make sure the repeatability and precision of welds. Blend with robotics and substance dealing with to produce automated producing cells.

Envision obtaining automatic alerts every time a machine needs to be serviced, a part altered, or simply a functionality repaired before the machine goes down and at just the appropriate time as part of your workflow to allow for max store movement whilst your machine is offline. That is definitely what synthetic intelligence can conceivably accomplish when put together with CNC machines.

The bar does the moving as an alternative to the Device. Most of the cutting is done right next to the collet. This differs from a CNC turning center the place the cutting takes place as being the Software moves into the bar. Swiss Lathes are perfect for higher production perform. When mixed with a bar feeder, They are really designed to operate lights-out and create parts unattended. With correct programming and operator input, they are able to make specific parts to specification with a large level of repeatability, usually with cycle times underneath a moment.

Not numerous machine retailers can boast of really competent CNC mill operators; as a result, there are already lots of horror stories about very low-excellent machined parts.

Info sets are important to encouraging operators get insight on how a machine functions and, ultimately, how a whole flooring of machines perform in sync with one another.

In the end, more know-how and better final decision producing cause significantly less shed time with the shop floor. Scheduling routine maintenance, Arranging jobs, and facilitating increased production all grow to be realities as a result of machine Mastering and also the artificial intelligence software that generates it.

At CNCMachines.com, we convey collectively a wealth of knowledge and assets to help you businesses navigate the entire world of CNC machining. From CNC mills and lathes to various components and best manufacturing brands, we aim to debate almost everything you should continue to be forward inside the quickly evolving production industry. Our platform not only allows you realize the latest advancements in CNC technology but additionally connects you with dependable solutions for improving precision, efficiency, and productivity in the operations.

Some CNC machines that Merge sorts of machining, fabrication, 3D printing, welding, and more for unique applications. Used CNC are capable of creating very complicated parts and assemblies with exact tolerances and amazing repeatability.

Some failures could cause a lot missing time that take advantage of just one production operate vanishes completely. Knowing your machines is significant to maintain the store floor buzzing along.

Machine Understanding algorithms, by way of steady Evaluation of operational info, can optimize machine functions. Whether it’s altering the spindle pace or optimizing Instrument paths, ML ensures that the machine operates at peak efficiency, lessening squander and enhancing product quality.

Two classes wherever synthetic intelligence Gains CNC manufacturing by far the most are in productivity and efficiency. It could be argued that every single advantage of AI and deep machine Mastering will directly or indirectly effect the core values of shop productivity and efficiency.

Artificial Intelligence (AI) and Machine Finding out (ML) represents an important evolution in Laptop or computer science and info processing systems which may be used in an effort to enrich virtually every technology-enabled service, merchandise, and industrial apps. A subfield of synthetic intelligence and computer science is named machine Discovering which focuses on employing facts and algorithms to simulate learning process of machines and improve the precision of the systems. Machine Mastering systems may be applied to the cutting forces and cutting tool have on prediction in CNC machine tools so as to increase cutting Instrument life through machining operations. Optimized machining parameters of CNC machining functions can be attained by utilizing the Highly developed machine Finding out systems so as to increase efficiency through part producing processes.

Artificial intelligence can forecast when machines need to be serviced and gauge the best time to do so. By Doing work with a established of data that is definitely connected to your production runs, operate times, machine productivity, and Device everyday living, AI can forecast optimal moments for servicing and machine tune-ups.

Woodworking: Woodworkers rely on modern CNC machines to immediately, correctly and exactly craft a wide range of wood objects. From cupboard Web producing and home furniture developing tasks to generating intricate carvings or comprehensive engravings, MultiCam CNC is the check out technology for these industries.

Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Michael Jordan Then & Now!

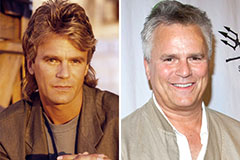

Michael Jordan Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!